CRM Industry Processes

Please note that this content is under development and is not ready for implementation. This status message will be updated as content development progresses.

The CRM supply chain is a complex, multi-tiered network that is determined by the global distribution of resources, the involvement of various stakeholders, technological and environmental challenges, market dynamics, and the inherent risks and dependencies within the chain.

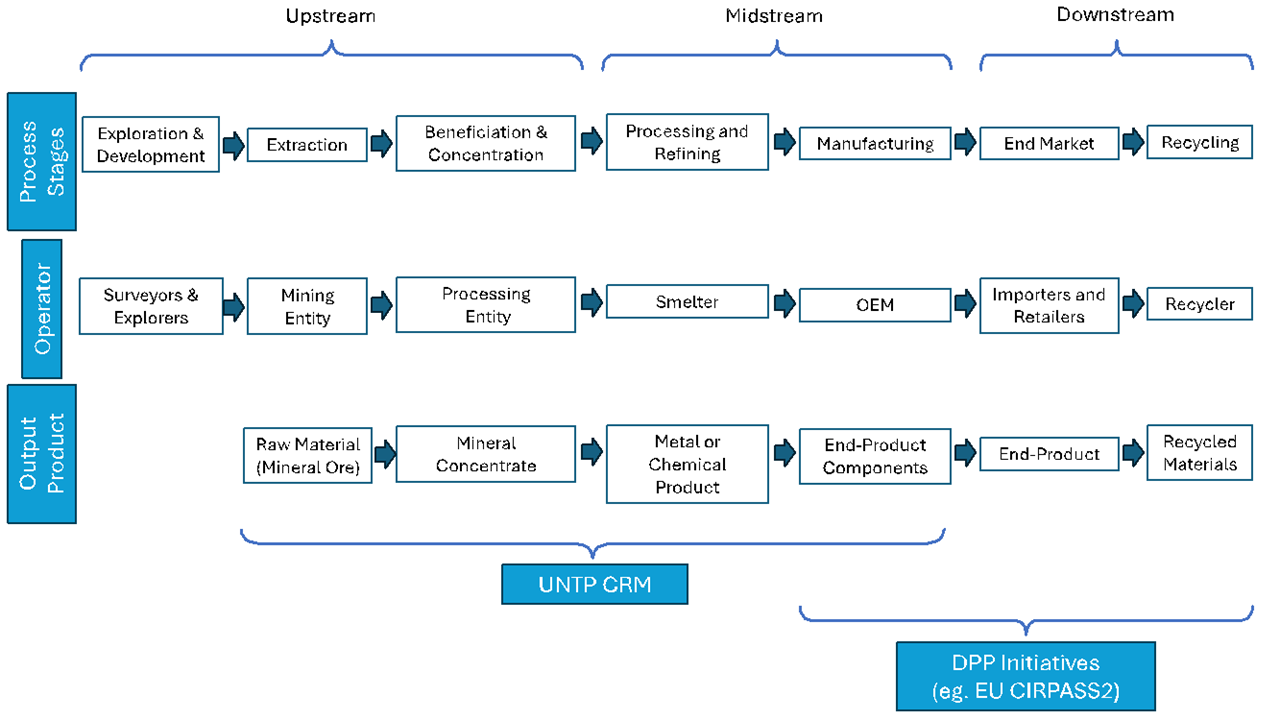

Although the supply chain structure for specific CRM commodities may vary, a general mineral or metal CRM supply chain of process stages, operator, and output product can be defined as below:

The CRM supply chain (metal and mineral) is composed of several distinct process stages including the flow of goods and services from the initial source, to the end consumer, and beyond to the post-consumption stage (recycling). All supply chain stages are connected by transport and logistics.

These stages represent the various processes involved in the production, transportation, and consumption of CRM products. The key identified business process stages, economic operators, and output products are described below. The UNTP-CRM project focuses mainly on the upstream production stages to the point of product assembly and market entry.

Process Stages

- Exploration and Mine Development: The initial and foundational stage is crucial for identifying new sources of raw materials and establishing the necessary infrastructure to extract these resources. It involves a combination of geological, technical, financial, and regulatory activities aimed at discovering and assessing mineral deposits. This is followed by the preparation of the identified deposit for full-scale mining. This includes designing and constructing the necessary infrastructure, obtaining permits, and setting up the operations required to extract and process the minerals.

- Extraction: This stage involves obtaining raw materials from the environment and is often referred to as the mining or harvesting phase. It includes identifying the locations of these materials, usually through geological knowledge, and developing methods to extract them from those locations, such as mining ores.

- Beneficiation and Concentration: The primary purpose of this stage is to increase the concentration of valuable minerals within the ore, thereby improving the quality and economic value of the raw material before further processing or refining. Usually, a product undergoes various processing steps, including crushing, grinding, and separation techniques such as flotation, magnetic separation, or gravity separation. The concentration process increases the proportion of valuable minerals relative to the total volume of material, making it more economically viable to transport and further process the material to extract the desired metals or minerals.

- Processing and Refining: CRM concentrate undergoes processing and refining to increase purity and prepare them for industrial use. This stage is energy-intensive and requires specialized facilities, often located in a few countries with the necessary technology and infrastructure. The refining process separates valuable materials from impurities, producing a marketable product.

- Manufacturing: The refined materials are used in the manufacturing of components or final products. This stage includes the production of high-tech components, such as batteries, semiconductors, and magnets, which are integral to modern technologies. The manufacturing process is often globalized, with different stages occurring in various countries, leading to a dispersed and interdependent supply chain.

- End-Market: CRM-containing products are imported and distributed to end-users, including industries and consumers. This stage involves further logistics and distribution channels to deliver products to their final destinations.

- Recycling: End-of-life products containing CRMs are collected, dismantled, and processed to recover valuable materials, which can be reintroduced into the supply chain. This step reduces dependency on raw material extraction and mitigates supply risks.

Economic Operators

- Geological Surveys and Exploration Companies: Specialize in identifying and evaluating mineral deposits. Provide expertise in geological assessments and feasibility studies of mineral reserves – confidence measured by the geological knowledge and data, while the extraction would be legally, economically and technically feasible.

- Mining Entity: A company operating mines and managing the extraction of raw material, or a provider of specialized mining services on a contract basis, often for large mining companies.

- Processing and beneficiation entities: Facilities that handle the initial processing of ores, including crushing, grinding, and preliminary separation. Companies focused on enhancing the quality of ore through physical and chemical processes.

- Smelter: An industrial facility that processes ores and concentrates on extracting and refining metals.

- Manufacturers: Companies that use critical raw materials to produce components and products.

- Importers, Distributors and Retailers: Facilitate the import movement of finished products from manufacturers to retailers or end-users, including cross-border import. Sell the final products to consumers or businesses.

- Recycling Entities: Specialize in the collection, processing, and recovery of valuable materials from end-of-life products.

Output Product

- Raw Material (Mineral Ore): Natural or processed resources are used as an input to a production operation for subsequent transformation into semi-finished and finished goods. Primary raw materials are, as opposed to semi-finished products, extracted directly from the environment and can be traded with no, or very little, further processing.

- Mineral Concentrate: A form of mineral ore in which the valuable minerals have been separated from the bulk of the waste material or gangue. Mineral concentrates can come in various forms depending on the type of mineral and the processing method used.

- Metal or Chemical Product: Materials produced at the refining stage from mineral concentrates to meet the required purity and quality standards for their intended applications. Those products can be pure, precious or industrial metals, specialty alloys, electronic-grade materials, chemical products or chemical precursors.

- Product Components: Specific product components transformed from refined metals and chemical products for a wide range of industries (electronic, automotive, renewable energy, etc.) and integrated into final end-products used by consumers, industries, and governments.

- End-Product: Products that are utilized in various industries and are essential to modern life, technology, and infrastructure. In the context of CRM, those products relate to the green energy and digital economy, such as EV vehicles, energy storage systems, electronic devices, etc.

- Recycled Materials: Recycled materials from end products are the valuable components or materials that can be recovered and reused after the product has reached the end of its useful life. In the context of CRM, those products are often metals or alloys.

Material Transformation Process at CRM Supply Chain Stages:

Post-mining stages in the CRM value chain consist of a series of operations and treatments that transform raw materials from a raw-material state into substances which are then used to make semi-finished and finished products. Those transformational operations and processes signify the complexity of the CRM supply chain and require a definitive capture as a transformative event of product output.

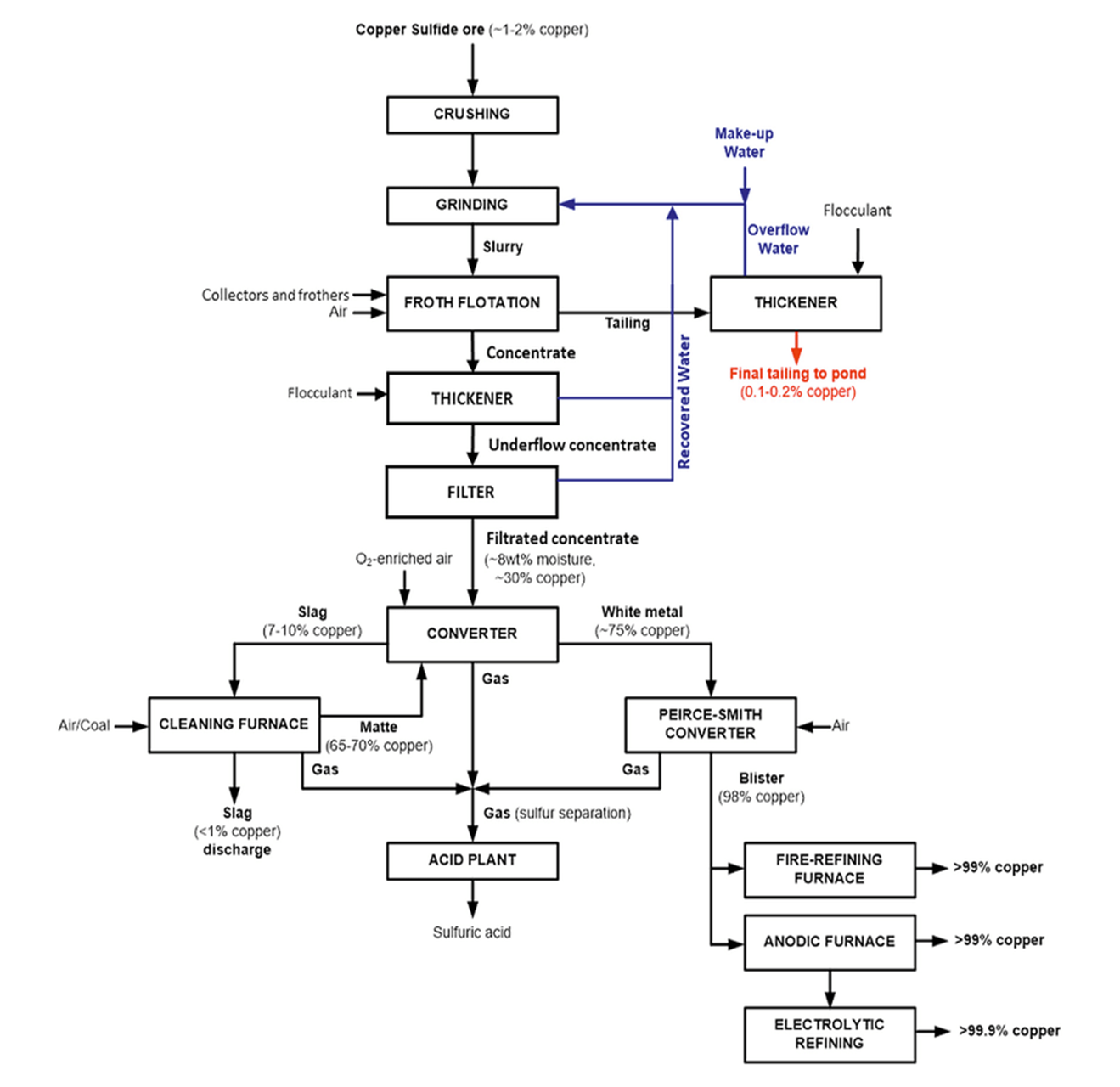

The key information about those processes can be captured through the industrial flow sheets. Also known as process flow diagrams (PFDs), Flow sheets are visual representations of the sequence of processes and equipment used in the manufacturing or processing of materials in an industrial setting. These diagrams illustrate the step-by-step flow of materials, energy, and information through different stages of production, from raw material inputs to finished products. For example, the figure below depicts a simplified flow sheet of the pyrometallurgical process for copper extraction:

Each Process Stage of the CRM Supply Chain (described above) has an industrial flow sheet. However, due to the greatly varying nature of CRM processing, transformational events should be addressed on commodity-specific flow sheets, e.g. Lithium, Copper and Cobalt supply chains. A flow sheet example for a copper mining operation is included in the Copper section below.